Offset lithography is the most used method for commercial printing on paper and board. In this article we’ll look at what offset litho printing is and how it works.

What is Lithography?

Lithography is a planographic form of printing, which basically means that the printing surface is flat. Image and non-image areas on the printing plate are on the same plane, with image areas accepting ink and non-image areas repelling it.

Lithographic printing or litho printing, relies on the principle that water and oily substances repel each other. In the printing environment, an image on a metal plate attracts the “oily” ink while the bare, moistened plate repels it.

The Offset Litho Process

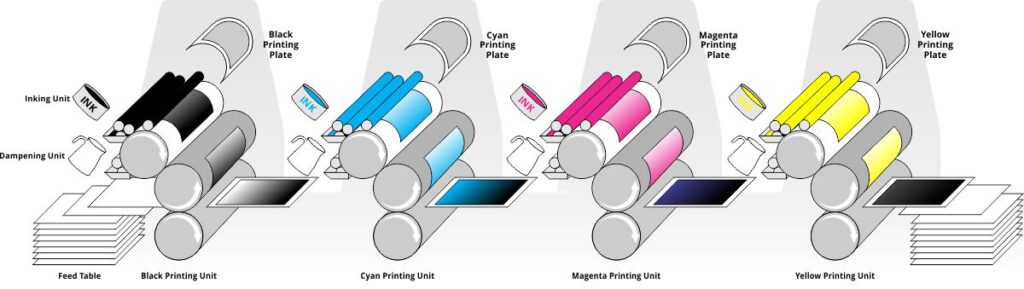

A metal plate with the image “burnt” on to it, is fitted to the plate cylinder on the printing press. The printing happens as the press cylinders rotate. Each time the cylinders rotate, the image area on the plate accepts ink from the ink rollers but repels water. The non-image area is cleared of ink by water.

An inked image is transferred to the blanket cylinder, covered by a smooth rubberised blanket. The blanket transfers ink to the paper as it is pressed between the blanket and impression cylinders. Because the blanket is an intermediate transfer medium, the process is known as “offset” litho.

If a second colour needs to be printed, ink from the first colour is replaced by the ink for the second colour. When dry, the printed sheets on the delivery table are moved to the feed table for a second pass.

Press speed is an important quality control variable in that the faster the press runs, the sharper the printing due to there being less dot gain.

Sheet-Fed Litho Printing

Sheet-fed litho is used for high quality, short to medium runs. The paper used ranges in size from A4 to A1. Blank paper is lifted off the feed table by suction and fed between the impression and blanket cylinders.

Web Offset Printing

Web offset is used for long run and volume printing as productivity is usually more important than quality. The web printing presses use large continuous reels of paper instead of sheets.

Spot Colour Printing

In spot colour printing, special pre-mixed inks are used for each colour on the printing press. This helps to achieve more precise and vibrant colours compared to the CMYK printing process. The Pantone Matching System (PMS) is widely used achieve colour consistency from one print run to the next.

Multi-Colour Printing

In multi-colour or process-colour printing, the original image is separated into its cyan, magenta, yellow and black components. A printing plate is made for each colour and the four plates then print the individual images onto one sheet of paper. The four colours are combined to reproduce the original image.

Printing presses have up to eight printing units so that the four colours can be printed along with special or spot colours and varnishes. Read more on spot and process colour printing.

Each unit needs to be set up exactly the same as the previous one for the colours to register properly on the printed sheet.

Colour Sequence

The traditional sequence for printing colours in offset litho printing was yellow first, magenta next, cyan third and black last. Yellow pigments used to contain lead chromate which made the yellow so opaque that it would mask other colours if it printed over them. With newer yellow and transparent yellow pigments, printers can now change the order in which colours are printed.

The trapping characteristics of inks also plays a major role in determining the best colour sequence. Yellow is usually printed last nowadays as most images have a high yellow content. Ink transfers better to paper than to wet ink so it makes sense to print the colours with smaller percentages first and leave yellow to the end.

Common Colour Sequences

| 4-Colour Presses | KCMY |

| 2-Colour Presses | CMYK |

| Single colour and proofing | CMYK |

Please feel free to contact us if you need help or advice with printing. Visit our home and services pages for more about us and what we do.

Please share this article if you found it useful

Leave a Reply